#Page under construction#

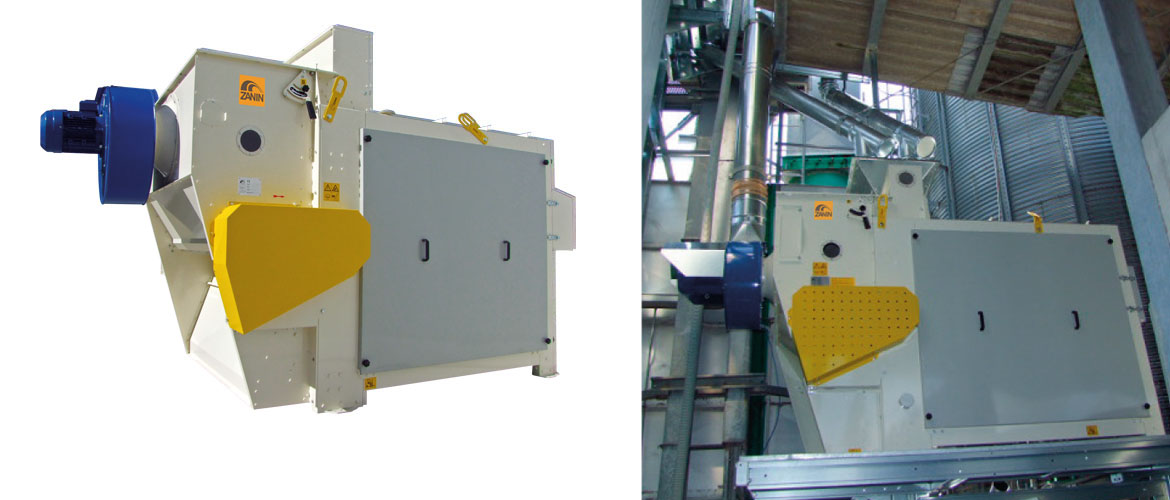

Cleaner PSC-S

The sieve cleaner allows to separate fine, medium and large impurities present in the product or calibrate with a double-pass system.

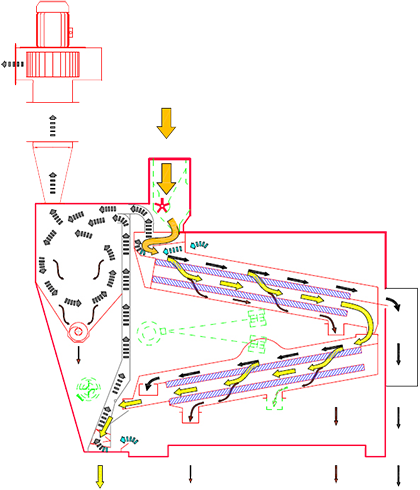

Nettoyeurs séparateurPSC-S operating principle

Psc double pass cleaning system.

The product enters by way of gravity into a balance distributor with counterweights and is uniformly spread

over the entire width. Subsequently it descends as an even curtain and encounters a cross air flow which

removes the lighter parts (decanted by a cyclone or filter), and deposits part of the dust and heavier impurities in

the decantation hopper, equipped with a reject discharge auger. The product, now clean from dust, enters the first

case with two levels of perforated sieves. These separate the product according to the perforation size. The product

proceeds to the second case with two levels of perforated sieves. Again the product is separated according to the

perforations. As it exits, the desired product is evenly spread over the entire width of the plane, and as it

descends in a thin curtain it again encounters a cross air flow. This removes any remaining dust and impurities still

present within the product. The cleaning and calibration system allows the separation of 7 types of waste and by-products.

Legend

Product with impurities inlet

Product with impurities inlet

Large impurities - Skin

Large impurities - Skin

Good product

Good product

Heavy rejects

Heavy rejects

Light rejects

Light rejects

Air

Air

Air with dust

Air with dust

Construction

- Pressed and bolted support frame for large cases.

- Fairing on pressed galvanized sheets.

- Product hopper entry.

- Volumetric distributor.

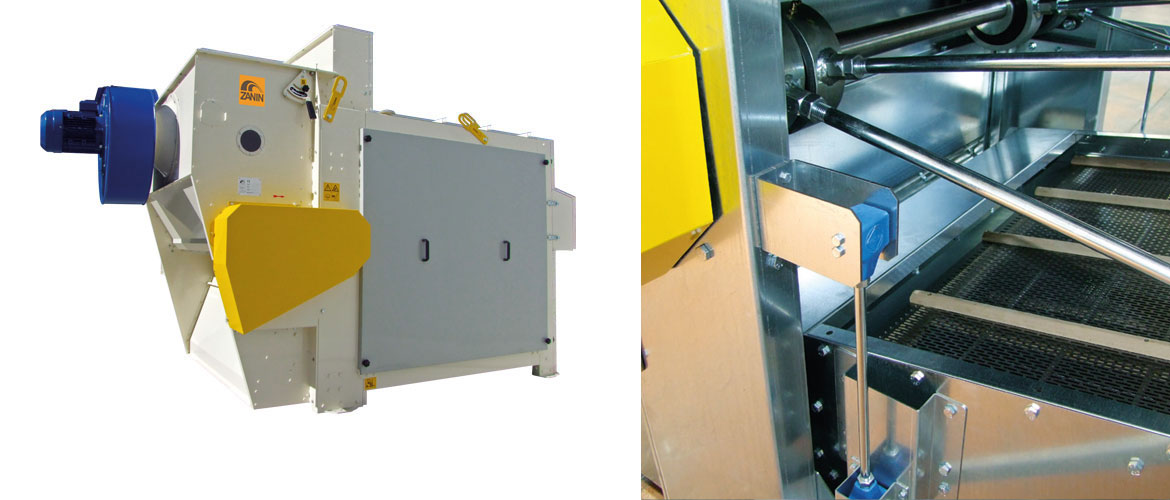

- Carbon steel sieves cases.

- Dust suction plug with vertical positioning.

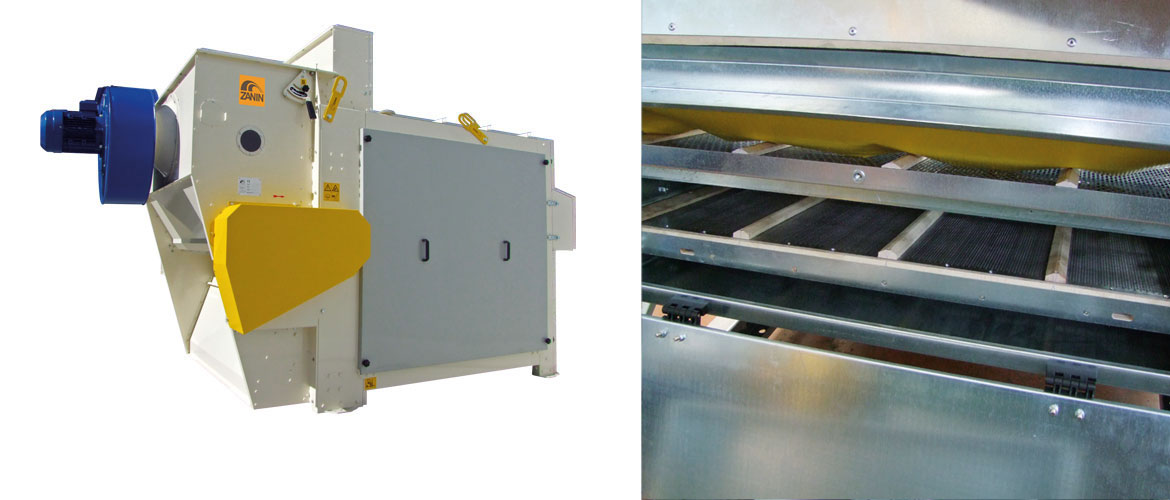

- Manual lock gate for air flow control.

- Carbon steel sieve cases (frame and frameholder) with cautschuk balls.

- Sieve movements through connecting rod.

Optional

- Antiwear sheet

- Switch board

- Vertical hopper for large impurities

- Inclined hopper for large impurities

- Collecting sector for by-products

- Support frame

- Bag placer

Specifications

Cleaning capacity from 4 to 10 t/h. Capacities calculated with wheat specific weight 0.78 t/m3 - RH 14% Impurities 2%.